Artificial intelligence (AI) is not just a buzzword; it’s a game changer in the realm of industrial automation. Imagine a factory where machines communicate with each other, learning and adapting in real-time to optimise production processes. This is not a scene from a sci-fi movie; it’s the reality we are stepping into. AI is revolutionising industries by enhancing efficiency, reducing operational costs, and improving safety standards. But how exactly is this technology reshaping the manufacturing landscape?

Firstly, AI plays a pivotal role in streamlining operations. By analysing vast amounts of data, AI algorithms can pinpoint bottlenecks in production, predict equipment failures, and suggest improvements. For instance, predictive maintenance technologies can forecast when a machine is likely to fail, allowing companies to perform maintenance before a breakdown occurs. This not only saves time but also significantly reduces costs associated with unexpected downtimes.

However, the transition to AI-driven systems is not without its challenges. Companies must navigate issues such as cost implications, data quality, and the need for workforce adaptation. Integrating AI requires substantial investment, and businesses must weigh these costs against the potential returns. Moreover, the effectiveness of AI solutions hinges on the quality of data fed into them. Poor data can lead to inaccurate predictions, ultimately hampering productivity.

As we explore the future, it’s clear that AI will continue to evolve, leading to exciting trends like AI-driven robotics and the Internet of Things (IoT). These advancements promise to create smarter factories where machines not only work efficiently but also collaborate seamlessly with human workers. The question remains: are we ready to embrace this technological revolution?

In conclusion, AI is set to transform industrial automation profoundly. From enhancing efficiency to addressing the challenges of implementation, the journey is just beginning. As we look ahead, one thing is certain: the fusion of AI and automation will redefine the way we approach manufacturing and production processes.

The Role of AI in Enhancing Efficiency

Artificial Intelligence (AI) is revolutionising the industrial landscape by significantly enhancing operational efficiency. By leveraging advanced algorithms and machine learning, AI streamlines processes in ways that were previously unimaginable. For instance, AI can analyse vast amounts of data at lightning speed, allowing businesses to optimise production schedules and reduce waste. Imagine having a virtual assistant that not only predicts machine failures but also schedules maintenance before a breakdown occurs; this is the power of AI in action.

One of the most compelling benefits of AI is its ability to reduce downtime. In manufacturing, every minute of downtime can lead to substantial financial losses. AI systems can monitor equipment health in real-time, identifying potential issues before they escalate. This proactive approach not only saves money but also ensures a smoother workflow. Companies that implement AI-driven solutions often report a remarkable improvement in their resource allocation efficiency.

To illustrate the impact of AI, consider the following table that highlights key areas where AI enhances efficiency:

| Area | AI Contribution |

|---|---|

| Production Scheduling | Optimises timelines based on real-time data. |

| Quality Control | Utilises image recognition to detect defects. |

| Inventory Management | Predicts stock levels to minimise excess. |

| Energy Consumption | Analyses usage patterns to optimise costs. |

Moreover, the integration of AI in industrial settings fosters a culture of innovation. Companies are now encouraged to explore new technologies and methodologies, leading to an environment where continuous improvement is the norm. This shift not only enhances productivity but also boosts employee morale, as workers see tangible results from their efforts.

In conclusion, the role of AI in enhancing efficiency cannot be overstated. As industries continue to evolve, those who embrace AI will find themselves at the forefront of innovation, ready to tackle challenges with unprecedented agility. For further insights on AI’s impact on industry, check out this article from Forbes.

Challenges of Implementing AI Solutions

This article explores the impact of artificial intelligence on industrial automation, examining its benefits, challenges, and future trends in various sectors. Discover how AI is transforming the landscape of manufacturing and production processes.

AI technologies streamline operations by optimising processes, reducing downtime, and improving resource allocation. This section delves into specific applications that enhance productivity in industrial settings.

Implementing AI solutions in industrial settings is not without its challenges. While the benefits are substantial, companies often face significant hurdles that can impede their progress. One of the primary issues is the cost associated with adopting AI technologies. Initial investments can be daunting, and many businesses struggle to justify these expenses without clear, immediate returns on investment.

Another major challenge is data quality. AI systems thrive on high-quality data, yet many organisations grapple with inconsistent or poorly managed data. This can lead to inaccurate predictions and ineffective automation, ultimately undermining the intended benefits of AI integration. To illustrate this, consider the following table:

| Data Quality Issue | Impact on AI |

|---|---|

| Inconsistent Data | Leads to unreliable AI outcomes |

| Missing Data | Results in gaps in analysis |

| Outdated Data | Causes misalignment with current trends |

Moreover, the workforce must adapt to these new technologies. As AI evolves, there is a pressing need for training and skill development. Companies must invest in continuous education to ensure their employees can effectively collaborate with AI systems. This is not just about technical skills; it’s also about fostering a culture of adaptability and openness to change.

Finally, navigating the complexities of change management is crucial. Employees may feel threatened by AI, fearing job loss or displacement. Addressing these concerns transparently can help ease the transition and promote a more harmonious integration of AI into the workplace. How can companies effectively manage this change? By actively involving employees in the process and providing reassurance about their roles.

Data Management and Quality Issues

In the realm of industrial automation, the significance of data management cannot be overstated. Effective integration of artificial intelligence hinges on the availability of high-quality data. Poor data quality can lead to flawed algorithms, which in turn may result in inefficiencies and increased operational costs. Imagine trying to navigate a ship with a faulty compass; similarly, businesses attempting to harness AI without reliable data are setting themselves up for failure.

One of the primary challenges is ensuring that the data collected is both accurate and relevant. Companies must develop robust data management strategies to address these issues. For instance, implementing data cleaning processes can help identify and rectify inconsistencies. Additionally, organisations should consider adopting data governance frameworks to maintain data integrity and compliance.

| Data Quality Issues | Impact on AI |

|---|---|

| Inaccurate Data | Leads to incorrect predictions and decisions |

| Inconsistent Data | Causes confusion in AI algorithms |

| Incomplete Data | Results in gaps in analysis and insights |

Moreover, as AI systems evolve, so must the data management practices. Companies are encouraged to invest in training their teams on the importance of data quality and management. By fostering a culture that prioritises data integrity, organisations can significantly enhance their AI capabilities. This not only improves operational efficiency but also builds trust in the AI systems being implemented.

In conclusion, addressing data management and quality issues is vital for successful AI integration in industrial automation. As the landscape continues to evolve, businesses must remain vigilant, ensuring that their data practices are as robust as the technologies they employ. For further reading on effective data management strategies, check out Data Governance Institute.

Training and Skill Development

As we venture deeper into the realm of artificial intelligence (AI), the importance of training and skill development cannot be overstated. The workforce must evolve alongside AI technologies to harness their full potential effectively. Without this crucial adaptation, companies risk falling behind in an increasingly competitive landscape. But what does this training entail? It’s not just about understanding new software; it’s about fostering a culture of continuous learning and adaptability.

To ensure employees are well-equipped to collaborate with AI systems, organisations should implement comprehensive training programmes that focus on various aspects:

- Technical Skills: Employees need to be trained on how to operate AI tools and software, which can significantly enhance their productivity.

- Data Literacy: Understanding data is vital. Staff must learn how to interpret and manage data effectively, as AI relies on high-quality input.

- Soft Skills: Communication and teamwork are essential. Employees should be able to work alongside AI and their human colleagues seamlessly.

Moreover, companies should consider establishing partnerships with educational institutions to provide ongoing training opportunities. This approach not only enriches the workforce but also creates a pipeline of skilled individuals ready to tackle the challenges posed by AI integration. As noted by industry experts, “The future of work is about collaboration between humans and machines,” which underscores the necessity for a well-trained workforce.

In conclusion, investing in training and skill development is not merely a checkbox for compliance; it is a strategic move that can yield significant returns. As we look towards a future where AI plays an integral role in industrial automation, organisations must prioritise these initiatives to remain competitive. For more insights on AI in the workplace, consider visiting Forbes.

Cost Considerations for Businesses

When it comes to integrating artificial intelligence into industrial automation, businesses must carefully assess the financial implications. The initial investment can be daunting; however, understanding the long-term benefits is crucial. Companies often face a trade-off between upfront costs and potential savings through increased efficiency and reduced operational downtime. For instance, the average cost of implementing AI solutions can range from £50,000 to £500,000, depending on the complexity of the systems involved.

Moreover, it’s essential to consider ongoing expenses, such as maintenance and updates, which can add to the overall budget. To illustrate these costs, the table below provides a breakdown of typical expenses associated with AI integration:

| Cost Category | Estimated Cost (£) |

|---|---|

| Initial Software Purchase | £20,000 – £200,000 |

| Hardware Upgrades | £10,000 – £100,000 |

| Training and Development | £5,000 – £50,000 |

| Ongoing Maintenance | £2,000 – £20,000 per year |

Additionally, businesses must not overlook the importance of training their workforce to effectively use these new technologies. Investing in staff development can significantly enhance the return on investment. Companies that allocate resources to upskilling their employees often find that they achieve a smoother transition and better overall performance. After all, a well-trained team can leverage AI to its fullest potential, making the initial costs seem less burdensome in retrospect.

In conclusion, while the cost considerations for adopting AI in industrial automation can be substantial, the long-term benefits often outweigh these initial expenses. By carefully planning and investing in both technology and training, businesses can position themselves for success in an increasingly automated world. For more insights on AI in business, check out Forbes.

Workforce Adaptation and Change Management

As we plunge deeper into the era of artificial intelligence, the adaptation of the workforce becomes a pivotal concern for industries worldwide. The introduction of AI technologies is akin to introducing a new player in a well-rehearsed orchestra; it requires not only skillful musicians but also a conductor who can harmonise the new with the existing. Employees may feel a sense of uncertainty, often questioning their roles and the future of their jobs. This is where effective change management strategies come into play.

To foster a culture of adaptability, companies must prioritise open communication. Employees should be informed about the changes AI will bring, not just in terms of technology but also regarding their own roles. Regular workshops and training sessions can serve as platforms for employees to express their concerns and learn how to work alongside AI. In fact, studies show that organisations that invest in training and development see a 30% increase in employee satisfaction and productivity.

Moreover, it’s essential to highlight the benefits of AI, such as enhanced efficiency and reduced mundane tasks. By showcasing real-life examples of successful AI integration, companies can diminish fears and encourage a more positive outlook towards these changes. For instance, Forbes outlines how companies like Siemens have effectively integrated AI into their manufacturing processes, leading to increased productivity and job satisfaction.

In conclusion, the path to successful workforce adaptation is paved with clear communication, ongoing training, and the demonstration of AI’s benefits. By taking these steps, organisations can ensure that their employees not only embrace change but thrive in this new technological landscape.

Future Trends in AI and Automation

The landscape of industrial automation is rapidly evolving, largely due to the **influence of artificial intelligence (AI)**. As we look ahead, several key trends are emerging that promise to reshape how industries operate. One of the most exciting developments is the rise of **predictive maintenance** technologies. These systems leverage AI algorithms to analyse data from machinery and predict when maintenance is required, thereby reducing downtime and extending equipment life. Imagine being able to foresee a problem before it occurs—this is not just a dream; it’s becoming a reality in many industries.

Another trend to watch is the integration of **AI-driven robotics** into manufacturing processes. These advanced robots are not only capable of performing repetitive tasks with precision but are also learning from their environments and adapting to new challenges. This adaptability enhances productivity and safety, making workplaces **more efficient** and less prone to human error. For instance, companies like Robotics Business Review are showcasing how AI robots are transforming traditional manufacturing lines into smart factories.

Moreover, the **Internet of Things (IoT)** is playing a crucial role in this transformation. By connecting devices and machines, IoT enables real-time data sharing, which AI can then analyse to optimise operations further. This synergy leads to improved decision-making processes, allowing businesses to respond swiftly to market changes. As we embrace these technologies, we must also consider the **ethical implications** of AI in the workplace, ensuring that the benefits are shared equitably among all stakeholders.

| Trend | Description | Impact |

|---|---|---|

| Predictive Maintenance | AI systems predict equipment failures before they happen. | Reduces downtime and maintenance costs. |

| AI-Driven Robotics | Robots that learn and adapt to their tasks. | Enhances productivity and safety. |

| IoT Integration | Connecting devices for real-time data sharing. | Improves operational efficiency and decision-making. |

In conclusion, the future of AI and automation is bright, filled with opportunities for innovation and efficiency. As we navigate these trends, it’s essential for businesses to remain adaptable and proactive, ensuring they are not left behind in this technological revolution.

Predictive Maintenance Technologies

In the ever-evolving landscape of industrial automation, are emerging as a game changer. By harnessing the power of artificial intelligence and data analytics, these technologies enable businesses to foresee equipment failures before they occur. This proactive approach not only enhances operational efficiency but also significantly reduces maintenance costs. Imagine a world where machines can signal their own health status, much like a human visiting a doctor for a check-up; this is the essence of predictive maintenance.

At the heart of predictive maintenance lies data collection. Sensors embedded in machinery gather real-time data on various parameters such as temperature, vibration, and pressure. This data is then analysed using sophisticated algorithms to identify patterns and predict potential issues. For example, a sudden increase in vibration levels might indicate an impending failure in a motor, allowing maintenance teams to act before a breakdown occurs.

Moreover, the implementation of predictive maintenance can lead to a remarkable shift in how organisations approach their maintenance schedules. Instead of adhering to a rigid timetable, maintenance can become more dynamic and responsive. This not only saves time but also optimises resource allocation. A recent study by McKinsey showed that companies employing predictive maintenance could reduce maintenance costs by up to 30%.

However, it’s essential to consider the challenges associated with predictive maintenance. The reliance on high-quality data means that companies must invest in robust data management strategies. Poor data quality can lead to inaccurate predictions, resulting in unnecessary downtime or, worse, unexpected failures. Therefore, businesses should not only focus on technology but also on training their workforce to interpret data effectively.

In summary, predictive maintenance technologies offer a glimpse into the future of industrial operations. By embracing these innovative solutions, companies can enhance their operational efficiency, reduce costs, and ultimately gain a competitive edge in the market. As we continue to explore the potential of AI in industrial automation, the importance of predictive maintenance will only grow.

| Benefits of Predictive Maintenance | Impact |

|---|---|

| Reduced Downtime | Minimises production interruptions |

| Lower Maintenance Costs | Decreases unnecessary repairs |

| Extended Equipment Lifespan | Optimises asset performance |

| Improved Safety | Reduces the risk of accidents |

For further reading on predictive maintenance technologies, consider visiting McKinsey & Company.

AI-Driven Robotics in Manufacturing

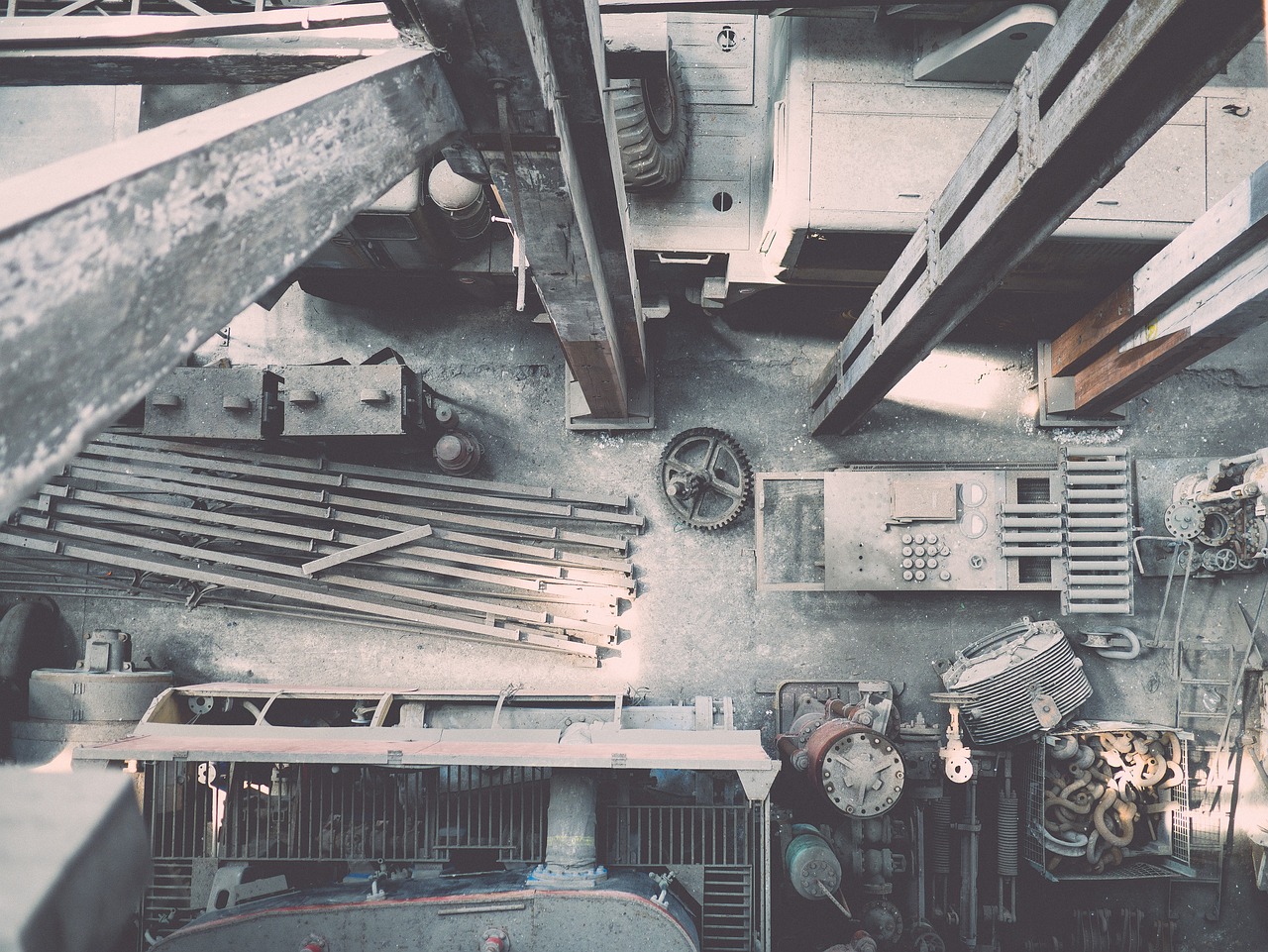

In the ever-evolving landscape of manufacturing, AI-driven robotics are emerging as a game-changer, revolutionising production processes and enhancing operational efficiency. These intelligent machines are designed to perform tasks that were once thought to be the exclusive domain of humans. Imagine a factory floor where robots not only assemble products but also learn from their environment, adapting to changes in real-time. This is not science fiction; it’s the reality of modern manufacturing.

The integration of AI into robotics allows for greater precision and speed in manufacturing. For instance, AI algorithms can analyse vast amounts of data from production lines, identifying inefficiencies and suggesting improvements that can lead to significant cost savings. According to a recent study, companies that have adopted AI-driven robotics have seen productivity increase by up to 30% while reducing operational costs by 20%.

Moreover, these robots are equipped with advanced sensors and machine learning capabilities, enabling them to make decisions independently. For example, in automotive manufacturing, AI-driven robots can detect defects in real-time, ensuring only the highest quality products leave the assembly line. This level of quality control is crucial in maintaining competitive advantage in today’s market.

However, the implementation of AI-driven robotics is not without its challenges. Companies must invest in training their workforce to work alongside these sophisticated machines. As the technology evolves, so too must the skills of the employees who operate them. This highlights the importance of ongoing education and adaptability in the workplace.

In conclusion, AI-driven robotics are not merely tools; they represent a fundamental shift in how manufacturing operates. As businesses continue to embrace this technology, we can expect to see even greater advancements in efficiency, quality, and safety. The future is bright for those ready to harness the power of AI in their manufacturing processes.

| Impact Area | Before AI | After AI |

|---|---|---|

| Productivity | 100 units/day | 130 units/day |

| Defect Rate | 5% | 1% |

| Operational Costs | £10,000 | £8,000 |

For more insights on AI in manufacturing, check out this comprehensive guide.

Frequently Asked Questions

- What are the key benefits of AI in industrial automation?

AI significantly enhances efficiency in industrial processes by optimising operations, reducing downtime, and improving resource allocation. It helps companies streamline their workflows, making them more productive and cost-effective.

- What challenges do companies face when implementing AI solutions?

Integrating AI into existing systems can be tough. Companies often grapple with high costs, data quality issues, and the need for workforce adaptation. It’s a balancing act to ensure that all aspects of the business are ready for such a transformation.

- How important is data quality in AI applications?

Data quality is crucial for effective AI implementation. Poor data can lead to inaccurate results and hinder the automation process. Companies must invest in robust data management strategies to ensure they have high-quality data for their AI systems.

- What role does workforce training play in AI adoption?

As AI technology evolves, ongoing training becomes essential. Employees need to develop new skills to work alongside AI systems effectively. This ensures that the workforce is not only prepared for change but can also leverage AI to its fullest potential.

- What future trends should we expect in AI and automation?

Looking ahead, we can anticipate exciting developments like predictive maintenance, AI-driven robotics, and the integration of the Internet of Things (IoT). These trends promise to revolutionise how industries operate, pushing the boundaries of efficiency and innovation.